FLEX AVS

Specifications

Product Specifications

Compatible with AVS (Adabptive Variable Suspension System)

AVS, available on some of Toyota & Lexus vehicles, normally has to be disabled when the suspensions are replaced with non-OE ones.

Well, that is no longer the case!

FLEX AVS enables ride height adjustment without deactivating AVS.

Newly-designed "AVS Needle" for damping force adjustment makes it possible to provide broader damping force adjustable range within the operating angle of AVS actuator.

*Damping force can NOT be adjusted manually.

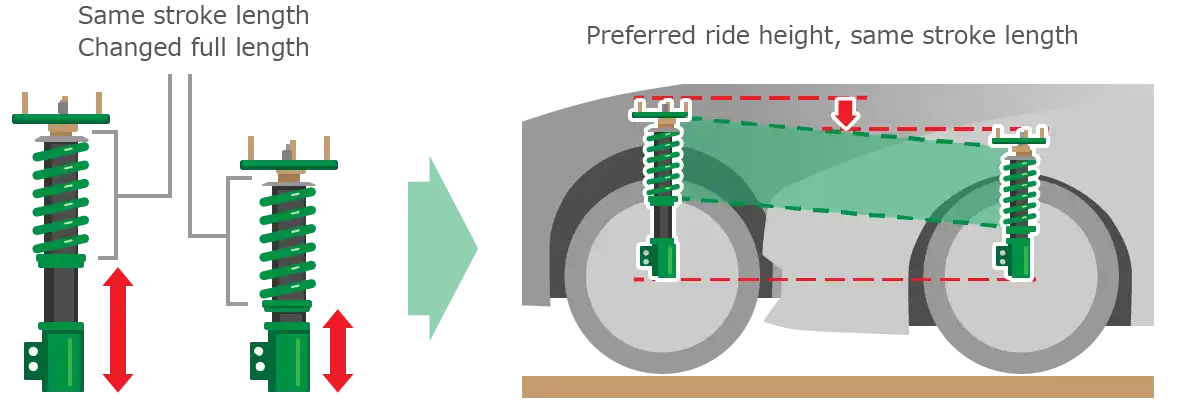

Full-Length Ride Height Adjustment

Advantage: adjusting ride height has little effect on ride quality.

In addition to combining a low down style with ride comfort, this system offers more setup options for sport driving too.

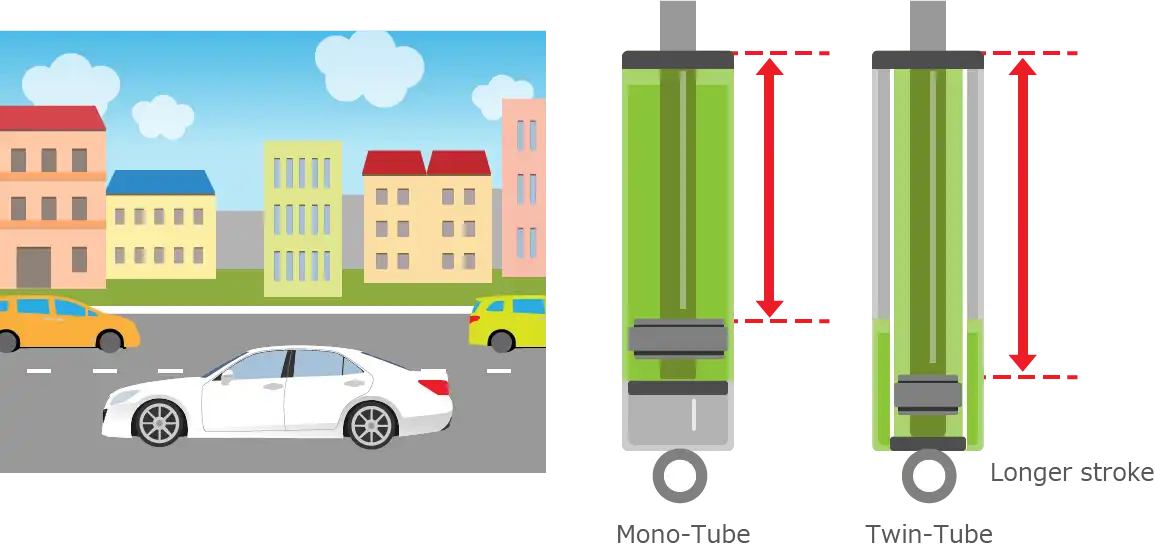

Twin-Tube

Compared to the regular mono-tube system, twin-tube attains longer strokes with a smaller repulsive force, resulting in high ride comfort.

Roads may have all sorts of surface conditions. This calls for shock absorbers with ample stroke, that operate smoothly.

Thanks to flexible strokes, you can negotiate gaps and bumps steadily on rough roads, meaning a smooth ride at low speed and stability at high speed.

Hydraulic Bump Stopper (H.B.S.)

More comfort and higher durability at maximum passenger and cargo load.

How the H.B.S. Mechanism Works

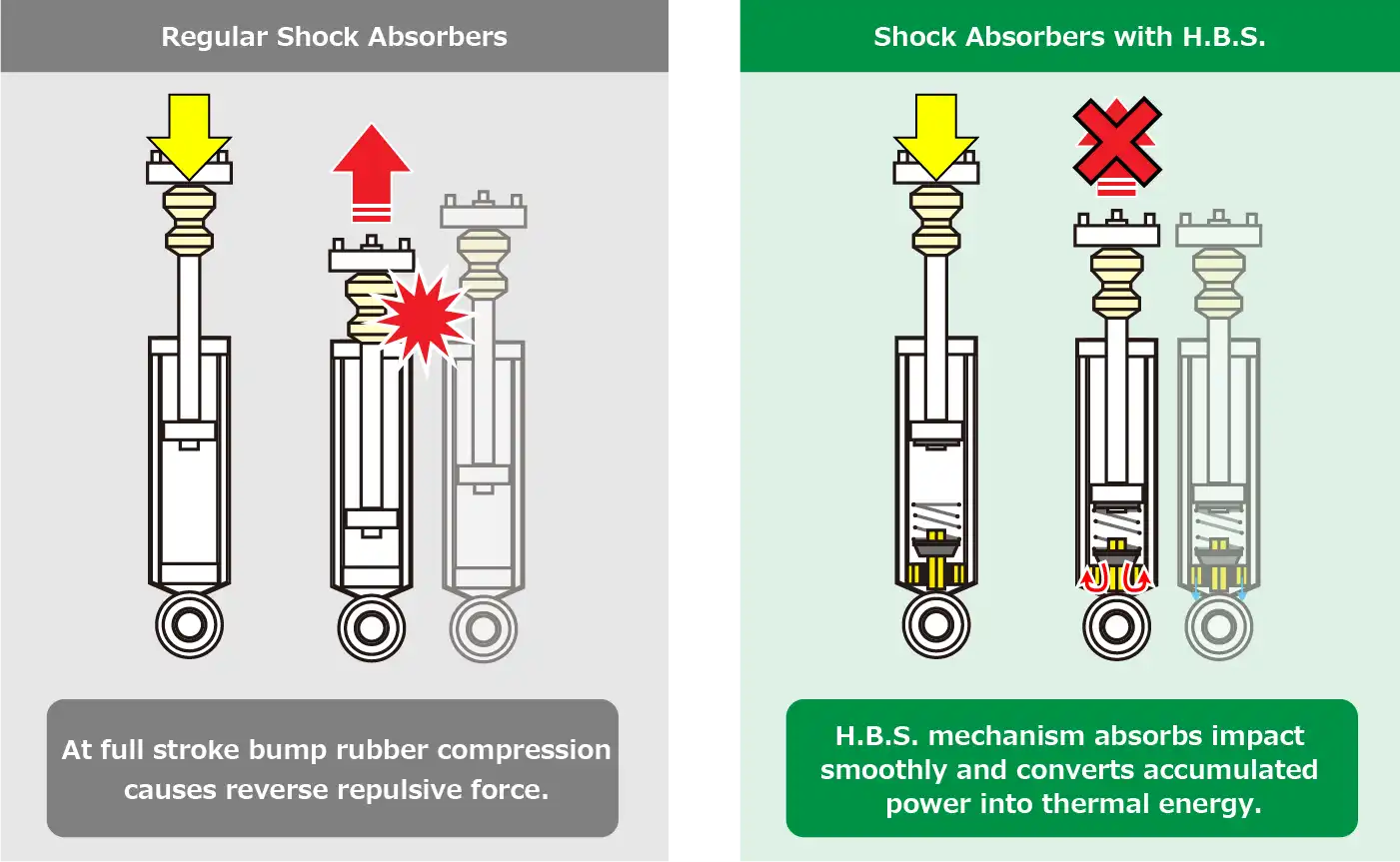

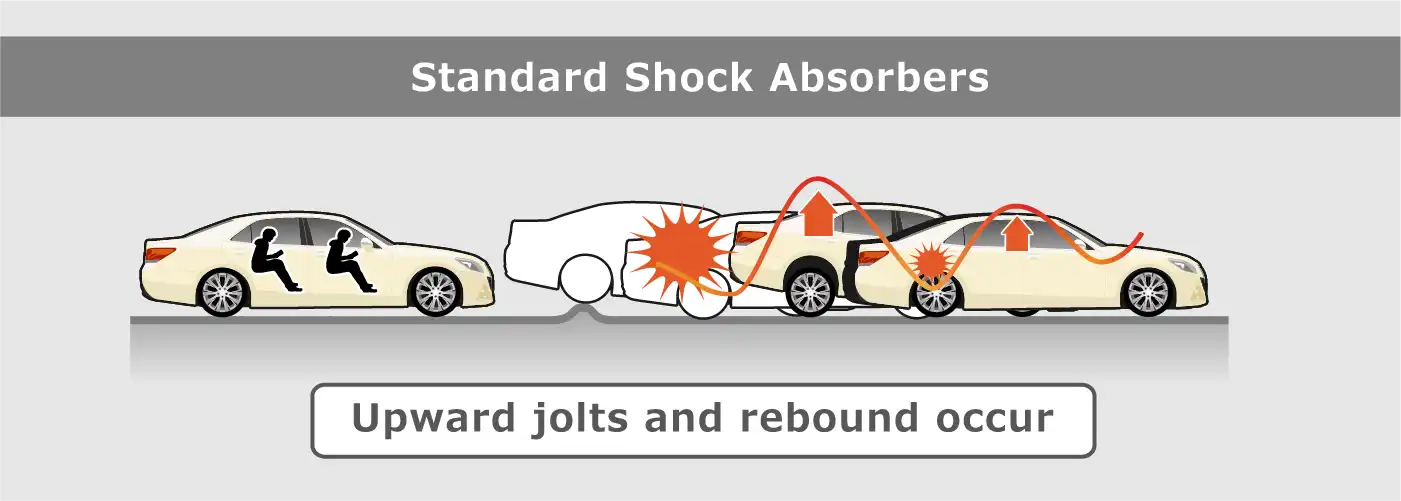

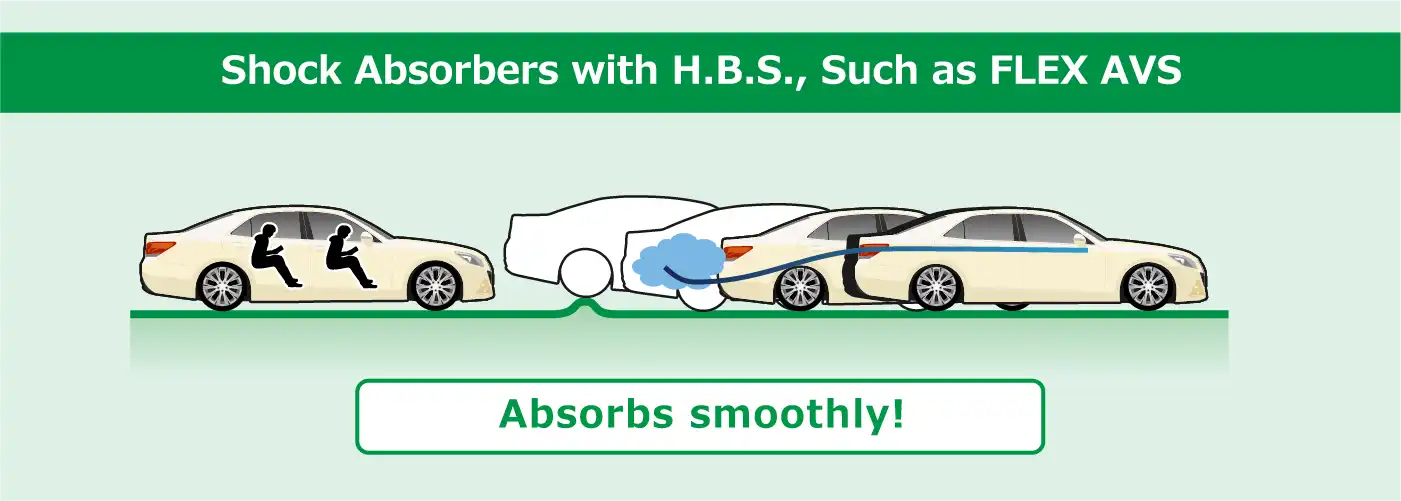

When regular shock absorbers fully stroke, their bump rubbers are compressed. The energy that is generated by that escapes as a repulsive force, which can disturb the vehicle's behavior. Furthermore, repeated full strokes can damage the damper.

In the same situation, FLEX AVS, featuring H.B.S., internally converts the impact of the stroke to thermal energy (heat) and absorbs it, strongly reducing the impact that disturbs the vehicle's behavior. With less damage to the dampers, H.B.S. also contributes to their durability.

The vehicle smoothly processes the impact, does not bounce, and its behavior swiftly stabilizes.

The Hydraulic Bump Stopper (H.B.S.) Mechanism

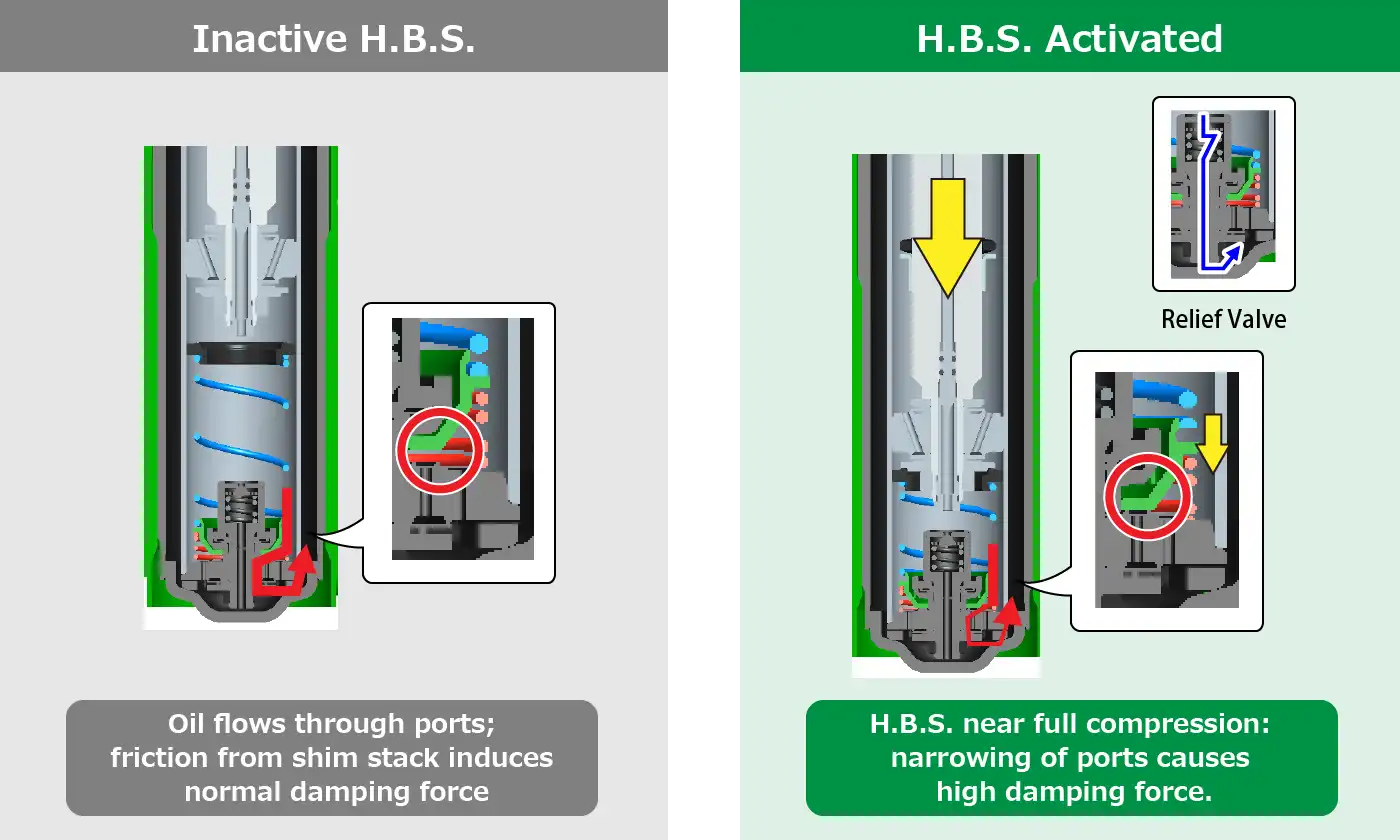

In shock absorbers with inactive or no H.B.S., the operative valve (green) floats, and oil flows freely through the base valve ports. Resistance to the flow from the shim stack then, causes damping force.

Near full compression, when the piston rod strokes beyond a predetermined point, the operative valve is pushed down and activates H.B.S.: the base valve ports are narrowed, blocking the oil flow. This results in high damping force.

A relief valve serves to suppress sudden damping force increase, when the pressure in the cylinder exceeds its regular level.

The setup of the H.B.S. mechanism is optimized per vehicle model, with the right activation point and damping force.

To avoid damages/breakages, conventional bump rubbers must also be fitted/used with H.B.S.-equipped dampers.

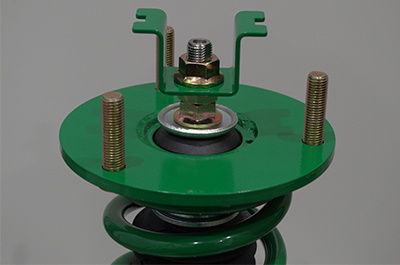

Mount Included

An easy-to-install mount, exclusively designed for each vehicle model, is included in the product kit.

- Reinforced Rubber Upper Mount

or

Pillow Ball Upper Mount

We have devised a suitable mount for each vehicle type.

Replacement Service

For this product we offer not overhaul, but a replacement service.

Our replacement service revives your shock absorber, by replacing the main part. It allows you to buy the shock absorber itself without the exterior parts like the upper mount, lower bracket, spring, etc.

Revalving is also available!

Damping Force Modification

This entails changing damping force to suit your driving conditions or preferences, by re-arranging the shock absorbers' internal components.

Stroke Modification

This entails changing the stroking distance to suit your driving conditions or preferences, by e.g. replacing or modifying the shock absorbers' internal components.

High Durability and Reliablility

Optimal Dust Boot

Thanks to its smooth compression and high durability, the dust boot guards the piston rod from damage, and keeps foreign material out of the shock absorber.

(Some vehicles use their OE dust boots)

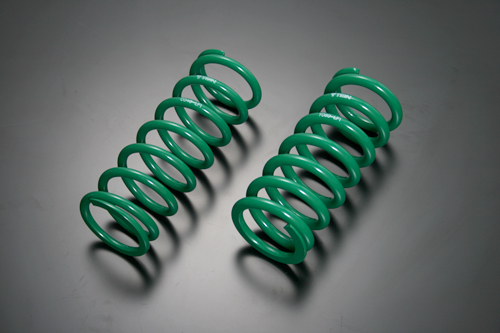

No-Sag Spring

Cold formed with SAE9254 steel (minimum tensile strength 200 kgf/mm2), our springs are outstandingly sag-proof and boast extreme resiliency.

Superior rust protection is ensured with a highly durable powder coating that does not peel or flake. Our high-quality springs can be used without worries, in any conditions.

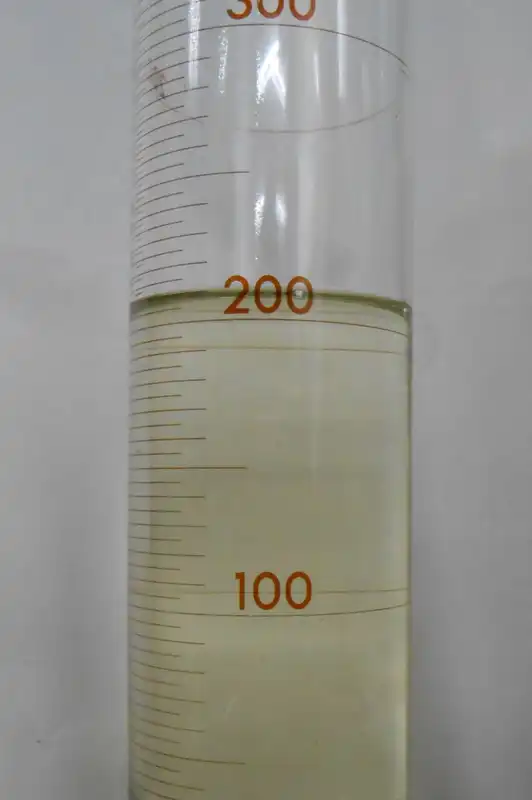

High-Performance Damper Oil

Since TEIN's damper oil maintains a stable viscosity in a broad temperature range, it sustains smooth stroke and reliable damping force in a variety of circumstances.

Due to excellent anti-foaming properties, it's resistant to cavitation (bubble forming). Since it withstands high heat too, it's suitable for intense sport driving as well.

Furthermore, the damper oil keeps up its superior performance long-term, because it's resistant to deterioration over time.

Rust-Proofing

TEIN-Green Powder Coating

A bright TEIN-green powder paint is used on the shock absorber's shell case. Our powder coating technique produces an extremely strong and durable barrier. No harmful organic solvents are used, for minimal pollution.

Superior durability and corrosion resistance are achieved by TEIN's patented 2-Layer, 1-Bake powder coating method, which uses 2 layers of anti-rust paint on a blasted surface.

(Japanese patent number 4347712)

Special Surface Treatment 'ZTP Coating'

Our unique special surface treatment ZTP Coating makes the paint strong against chipping by flying gravel, and further enhances its corrosion resistance.

With zero claims for stuck parts due to rust in 2,000,000 shock absorbers, TEIN shock absorbers are amazingly rustproof. We're confident of customer satisfaction even in coastal areas or regions with heavy snowfall.

>>We're confident of TEIN shock absorbers' surface treatment!